Loadmaster Roof Deck Assembly Structures

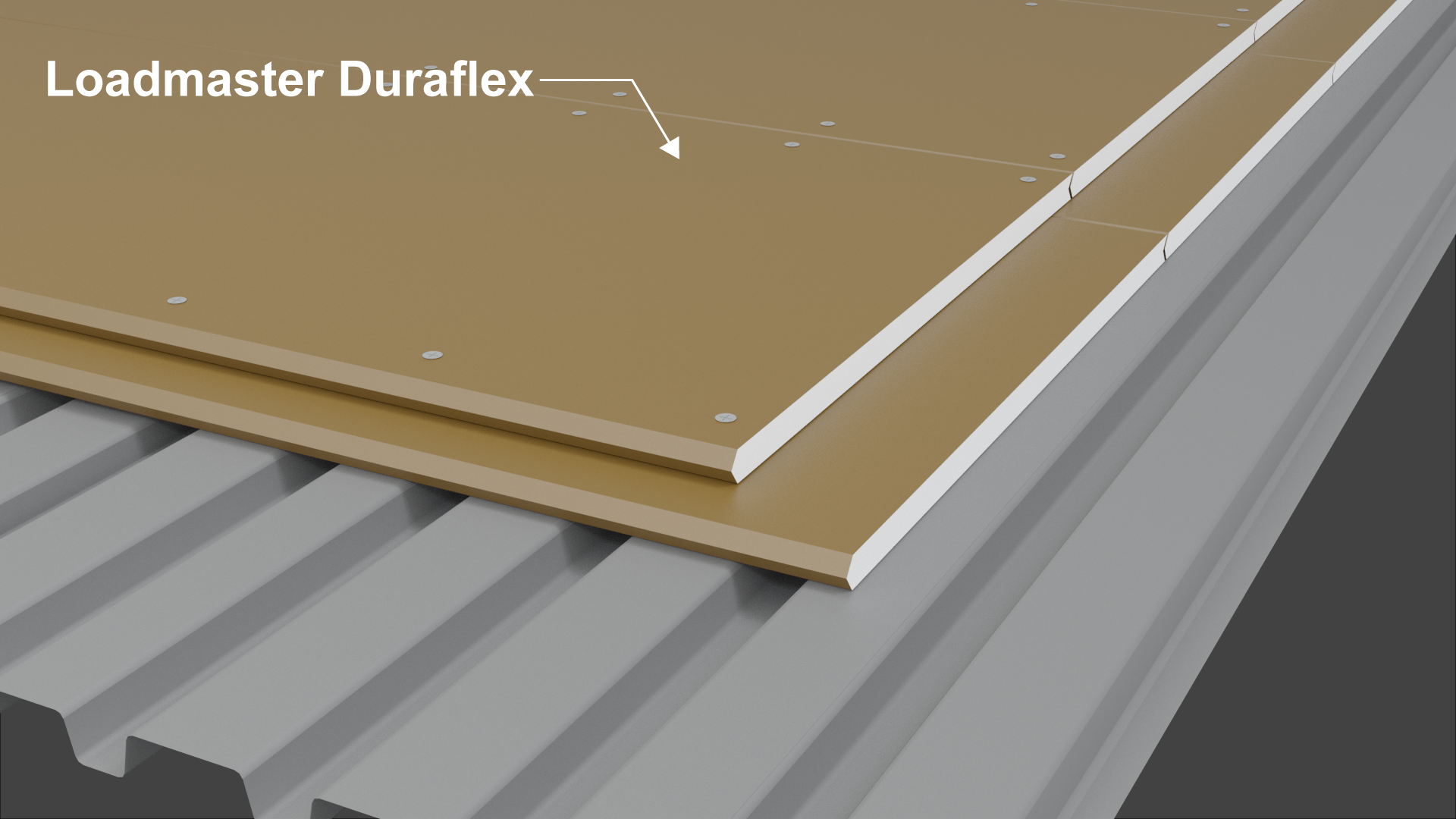

Duraflex is designed and engineered to provide an improved base for roof coverings. It is reinforced with glass fiber in its core and has tongue and groove edges to lock it into place, becoming a superior base for roof coverings. Roof coverings are bonded to the Duraflex surface using tested and approved adhesives and our high tensile steel sections are supplied in multiple thicknesses (from 9/16” to 7”) and gauges (from 26 to 14 gauge).

Loadmaster Basic Assembly

Basic Loadmaster Roof Deck Assemblies consist of our patented Duraflex Mineral Board and high tensile steel sections in various thicknesses and gauges.

Loadmaster Basic Nailable Assembly

Basic Nailable Assemblies consist of Loadmaster’s high tensile steel sections in multiple gauges (26 to 14 gauge) and two layers of Loadmaster 1/2" or 5/8" Duraflex Mineral Board. Steel sections are attached to the steel structure by screws or welding, with tongue and groove edges that are a unique feature of Loadmaster’s roof cover board. These two components are secured to each other with high performance screws in patterns that create structural composite capacity within the assembly. Roof coverings, such as shingles, tile or slate, are mechanically attached to the Duraflex Mineral Board Nailable surface.

Loadmaster Insulated Assembly

Insulated assemblies consist of Loadmaster’s high tensile steel sections in multiple gauges (from 26 to 14 gauge), our Isocyanurate Insulation and Duraflex Mineral Board, with its tongue and groove edges are designed and developed by Loadmaster. These components are secured with high performance screws in patterns that create structural composite capacity within the assembly and are bonded to the Duraflex Mineral Board surface on low sloped roofs and all sloped roof coverings are mechanically attached.

Loadmaster Insulated Nailable Assembly

Loadmaster’s Insulated Nailable Assembly consists of Loadmaster’s high tensile steel sections in multiple gauges (26 to 14 gauge), our Isocyanurate Insulation is covered by two Duraflex Mineral Boards and secured by tongue and groove edges. These components are secured with high performance steel screws in patterns that create the structural composite capacity of the assembly. Two Duraflex Mineral Boards over the insulation provide a nailable surface for sloped roof coverings and all sloped roof coverings are mechanically attached. This assembly can be created specifically to be used in fire rating designs. Contact Loadmaster Technical Department for details.

Loadmaster Insulated Dual Board Assembly

Our Insulated Dual Board Assemblies consist of Loadmaster’s high tensile steel sections in multiple gauges (from 26 to 14 gauge) a Loadmaster Duraflex Board placed on the steel section, our Isocyanurate Insulation, and a second Loadmaster Duraflex Mineral Board.

Duraflex was designed and developed by Loadmaster and is the only roof cover board with tongue and groove edges. These components are secured with high performance screws in patterns that create the structural composite capacity of the assembly. All low sloped roof coverings are bonded to the Duraflex Mineral Board surface and all sloped roof coverings are mechanically attached. These assemblies are used for Hourly Fire Rated designs of 1 to 3 hours.

Loadmaster Insulated Dual Board Nailable Assembly

An Insulated Dual Board Nailable Assembly consists of Loadmaster’s high tensile steel sections in multiple gauges 26 ga. to 14 ga., a Loadmaster Duraflex Board, Loadmaster Isocyanurate Insulation, and covered by two Loadmaster Duraflex Mineral Boards.

Duraflex was designed and developed by Loadmaster and is the only roof cover board with tongue and groove edges. The components are secured with high performance screws in patterns that create structural composite capacity of the assembly and two Duraflex Mineral Boards over the insulation provide a nailable surface for sloped roof coverings. All sloped roof coverings are mechanically attached and these assemblies are used for Hourly Fire Rated designs of 1 to 3 hours.

For more information or assistance contact your local Loadmaster Sales Representative. Find areas served, phone numbers and email addresses in Block 10.